Do you have your own stationary asphalt plant? If you’ve already bought an asphalt plant with a warranty, you’re right. Because quality asphalt plants can bring you a lot of profit. And if you haven’t had time to buy one yet, you can take a look at our products and see if this is the best place to buy an asphalt plant for you. Find out their prices and determine. I think you will find your desirable stationary asphalt plant here, for there are a variety of types available. Get in touch with us.

Stationary asphalt plant: description

As we all know, asphalt concrete mixture has already become unchangeable goods and materials since its appearance. Nowadays, asphalt roads have already spread everywhere in every country of the world, because asphalt-concrete plant was designed and manufactured. Its abbreviated name – abz, sometimes by it also are called asphalt plant or asphalt plant. Now I shall answer on a question set by people: what is abz? Abz is a special factory on asphalt manufacture, still you can understand large complex equipment for asphalt manufacture. You can say asphalt plants have made a major contribution to the infrastructure construction industry since its inception. They are often used to produce asphalt concrete in road construction projects. With continuous improvement, stationary asphalt batching plant has more asphalt capacity and longer shelf life for use. Are you interested in abz? If you want to buy asphalt plant, you still need to go further and learn more about it.

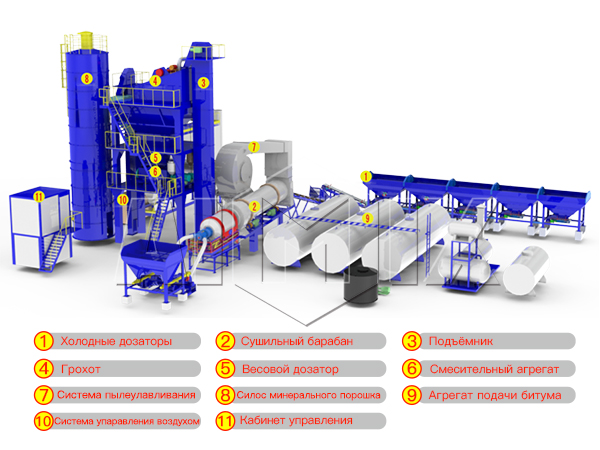

Asphalt Concrete Plant Working Principle

Asphalt plant is similar to concrete batching plant, but its working principle is more complicated than that of concrete mixing plant. That’s because asphalt batching plant is equipped with a heating device. To understand their working principle and working condition, you should clearly know, asphalt plant of what consists of and its scheme? Our stationary asphalt plant mainly consists of the following components: 1, Hopper batchers; 2, Drying drum for heating and drying the mixture; 3, Lifter; 4, Grinder; 5, Weight batcher for weighing bitumen and aggregate; 6, Mixer for mixing different mixtures; 7, Dust collection system; 8, Mineral powder silo; 9, Bitumen feeding unit; 10, Air control system; 11, Control room. How’s that? Now you must already understand how the asphalt concrete plant works, with the help of the lower diagram of the abz. If you want to know more information about our products, you can consult us. We will show and explain you clearly.

How to buy the right asphalt plant

Do you have experience for choosing an asphalt plant? Do you know the right quality asphalt plant to buy for yourself? These questions have been and will be important for you if you want good asphalt plants to buy at a low price. Because there is such an example, someone bought abz at high prices but not quality, and the parts for abz are difficult to buy. That case depends on the fact that the buyer does not know how to buy a stationary asphalt concrete plant correctly. I would like to share my advice with you here.

Clarification of your specific requirement

Which asphalt plant do you need? With what capacity? First, you need to clarify the scale and asphalt requirements of your construction project for which you want to buy an abrasive mixer. I suggest you ask a professional to help you assess it, if you yourself are not sure which stationary asphalt plant you need. Contact us, we can provide you with free and special services and advice. Find out and try it out!

Find out and compare prices for asphalt plants

The price of asphalt batching plants is always the main focus of buyers. You should also not ignore this factor before buying. You can get the prices from the official websites of the asphalt plant suppliers. While some websites have directly published the asphalt plant prices on the website. But those prices were usually not real, if you find out further, their actual prices have become more expensive. When you have got the abz prices, you need to do a neat analysis and comparison, and determine where to buy asphalt batching plant at low prices. After all, different asphalt plant suppliers have different prices. Get rational prices for yourself and your business.

Visit their manufacturers and production plant

At the end of the day, you need to visit those suppliers who have provided rational product prices. Check if their manufacturing plants and workshops produce quality asphalt plant. Only after these specific comparisons will you be able to buy a quality and excellent asphalt plant with a quality one.

Buy a better asphalt plant here

You can buy asphalt plants at a low price from our company AIMIX. Besides offering discounted prices, there are also the following reasons why you should choose our products.

⇒ the choice is large. In our company there are different types of asphalt plants for different construction projects.

⇒ The capacity is stronger. The company has released many models for customers, with capacity from 10 ton/hour to 320 ton/hour.

⇒ Our abz equipped with dust extraction device. It does not affect the air.

⇒ the company’s reputation is high. Reputation is an important factor formed in every trade.

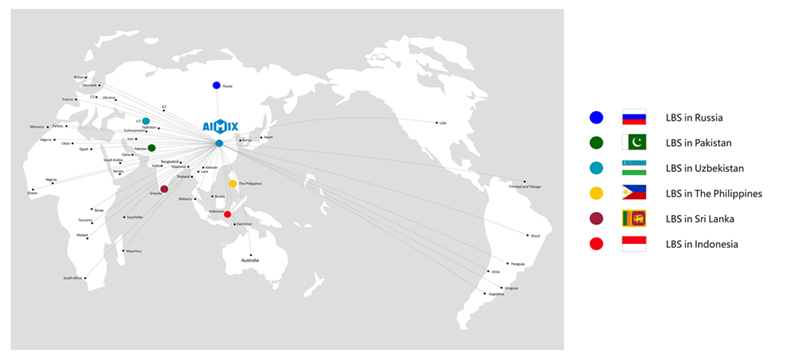

⇒ The after-sale service is the best. Our construction machinery has been exported to many countries all over the world. Especially in Kazakhstan, Uzbekistan, Russia, USA, etc. In this process, it has gradually formed a perfect service system.

Stationary Asphalt Plant – Technical Specifications:

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

| Performance | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Inert material supply system | |||||||||

| Inert material hopper volume | 4*4.5 м3 | 4*6.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 5*12 м3 | 5*12 м3 | 5*12 м3 | 6*15 м3 |

| Transport capacity | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 200 t/h | 220 t/h | 280 t/h | 360 t/h |

| Inert material heating and drying system | |||||||||

| Drying drum size | F1.2 m*5.2 m | F1.5 m*6 m | F1.5 m*6.7 m | F1.65 m*7 m | F1.8 m*8 m | F2.2 m*9 m | F2.6 m*9 m | F2.6 m*9.5 m | F2.8 m*10.2 m |

| Dryer capacity | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h | 240 t/h | 260 t/h | 360 t/h |

| Burner fuel consumption | 70-300kg/h | 100-400kg/h | 120-600 kg/h | 150-1000 kg/h | 150-1000 kg/h | 150-1400kg/h | 180-1800kg/h | 180-1800kg/h | 260-2500kg/h |

| Mixing tower | |||||||||

| Vibrating screen | 4 layers | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Inert material dosing hopper volume | 500 kg | 800 kg | 1000 kg | 1300 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4000 kg |

| Powder dosing hopper volume | 120 kg | 150 kg | 200 kg | 200 kg | 300 kg | 300 kg | 320 kg | 600 kg | 700 kg |

| Bitumen metering hopper volume | 100 kg | 120 kg | 150 kg | 150 kg | 250 kg | 250 kg | 250 kg | 480 kg | 500 kg |

| Mixing capacity | 500 kg | 800 kg | 1000 kg | 1,250 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4000 kg |

| Mixing cycles | 45 с | ||||||||

| Dust extraction system | |||||||||

| Filter pad | 230 м2 | 300 м2 | 420 м2 | 480 м2 | 550 м2 | 650 м2 | 700 м2 | 1050 м2 | 1350 м2 |

| Chimney power | 22 kW | 30 kW | 45 kW | 55 kW | 90 kW | 110 kW | 2*75 kW | 2*90 kW | 2*110 kW |

| Bitumen temperature | 140-180 ℃ | ||||||||

| Finished material hopper (options) | 20/50 tons | 20/50 tons | 20/50 tons | 60 tons | 60 tons | 120 tons | 120/200 tons | ||

| Total power consumption (depending on configuration) | 170 kW | 200 kW | 300 kW | 350 kW | 380 kW | 490 kW | 550 kW | 670 kW | 865 kW |

Would you like to know more or get their commercial offers?

Stationary asphalt plant: types

As an important major equipment in road construction, stationary asphalt paver has always occupied considerable market demand. Our company has designed and produced many models of abrasion ramps according to the demand of customers. I think you can find the suitable abrasive asphalt batching plant here too. Our asphalt plants can be divided into two types according to their mobility:

⇒ stationary asphalt plant;

⇒ The mobile asphalt batching plant.

And they can also be divided into two types according to the mixing method:

⇒ Asphalt plant of cyclic type;

⇒ Continuous asphalt plant.

The biggest asphalt concrete batching plant can produce asphalt mix up to 320 tons, such powerful capacity can bring you more profits.

The Best Asphalt Plant Manufacturer

Our company AIMIX was established in China in 1982. It is mainly engaged in the design, manufacturing and sales of the following construction machinery:

⇒ Concrete batching plants;

⇒ Dry mix mortar production line;

⇒ auto concrete mixer;

⇒ self-propelled concrete mixer with self-loading;

⇒ concrete pump trucks;

⇒ concrete pumps;

⇒ concrete mixer with pump;

⇒ brick and block making machine;

⇒ tower cranes and others.

Our company has passed the ISO9001 certification. In addition, our company has also obtained a number of certificates in its development process. Can you visit our company and confirm whether it is worthy of your trust?

What asphalt plant services we provide

On the service after the sale you have to attach great importance. Our company can offer many cordial services to customers who have already bought or want to buy asphalt plants in AIMIX. For example, installing an asphalt plant is a complex undertaking. But our technical engineers can help you. In addition, they can also teach you how to adjust and manage the equipment properly in operation. Interested? Contact us.

Mobile asphalt plant

A mobile asphalt plant is suitable for smaller projects. their capacity ranges from 10 tons to 160 tons per hour. Find out more here!

If you’re interested in our asphalt mixing plant or want to get their prices, you can contact us through the shout out button “Get Price”. Compare and find out where to buy an asphalt plant better. Good luck to you!