AIMIX specifically offers a variety of stationary and mobile asphalt plants, with a wide variety of quotations and options for customers. Are you interested in our products? This article is more about mobile asphalt plants. With a wide variety, the best service and low prices, you can be assured of getting a reliable asphalt mixing plant.

Mobile abc: its composition and design

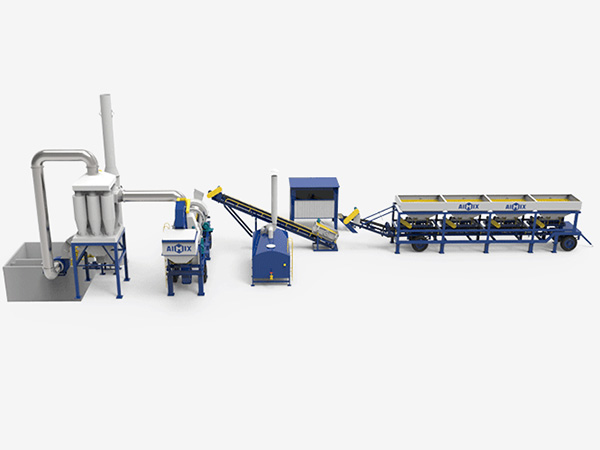

Themobile asphalt plant consists of the following:

⇒ Cold material feeder;

⇒ Drying and mixing device;

⇒ combustion devices;

⇒ hot mix lifting devices;

⇒ dust filter systems, asphalt feeding and spraying systems;

⇒ silos for storing the prepared asphalt mixture;

⇒ driving devices and electrical control system.

Among them, the dust filter system is a professional and advanced dust filtration device that can meet the environmental protection. This device also enables our mobile asphalt plant to meet the environmental protection standards of the importing country.

Mobile asphalt plant: classifications

Mobile asphalt plants refer to complex equipment. Since its inception, our company has a long history of production and research and development. In this process, our company has produced a variety of models. They can also be divided into many classifications. For example, according to its capacity, it can be divided into small and medium classifications. Their theoretical capacity ranges from 60 to 160 tons per hour, you can find out specifically in this table.

ALYQ Series Mobile Asphalt Plant

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 |

| Performance | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h |

| Inert material supply system | |||||

| Inert material hopper volume | 4*6.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 5*8 м3 |

| Belt power | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h |

| Inert material heating and drying system | |||||

| Drying drum size | F1.5 m*6 m | F1.5 m*6.7 m | F1.65 m*7 m | F1.8 m*8 m | F1.9 m*9 m |

| Dryer capacity | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h |

| Burner fuel consumption | 100-400/kg/h | 120-600/kg/h | 150-1000/kg/h | 150-1000/kg/h | 150-1400/kg/h |

| Mixing tower | |||||

| Vibrating screen | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers |

| Inert material dosing hopper volume | 800 kg | 1000 kg | 1300 kg | 1500 kg | 2000 kg |

| Powder dosing hopper volume | 150 kg | 200 kg | 200 kg | 300 kg | 300 kg |

| Bitumen metering hopper volume | 120 kg | 150 kg | 150 kg | 250 kg | 250 kg |

| Mixing capacity | 800 kg | 1000 kg | 1,250 kg | 1500 kg | 2000 kg |

| Mixing cycles | 45 с | ||||

| Dust filter (bag dust filter) | |||||

| Filter pad | 300 м2 | 420 м2 | 480 м2 | 550 м2 | 650 м2 |

| Chimney power | 30 kW | 45 kW | 55 kW | 90 kW | 110 kW |

| Bitumen temperature | 140-180 ℃ | ||||

| Total power (depending on configuration) | 200 kW | 300 kW | 350 kW | 380 kW | 490 kW |

Would you like to know more or get their commercial offers?

According to the principle of concrete mixers, they can be divided into two kinds:

⇒ Forced batch asphalt plant;

⇒ Continuous asphalt plant.

Simply said, the first type is equipped with compulsory concrete mixer, in the process of operation, only when you can feed new mixes into the mixing drum when you unload all the prepared mixes from the drum, although it seems too complicated, but the mixing efficiency of concrete mixer is high. And the second kind can do the feeding of mixture, mixing, and unloading of prepared mixture at the same time, its production procedures have been simplified, the operation is simple and easy. Which one do you like best? You can leave your contacts and email to get detailed information and preferential prices.

Mobile drum type concrete batching plant Series ALT

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 | |

| Performance | 20 t/h | 40 t/h | 60 t/h | 80 t/h | 100 t/h | |

| Total capacity | With diesel fuel | 34 kW | 65 kW | 105 kW | 135 kW | 170 kW |

| With coal heating | 40 kW | 75 kW | 120 kW | 165 kW | 200 kW | |

| Inert material supply system | 3.5 м3 *1 | 4 м3 *4 | 4 м3 *4 | 6.5 м3 *4 | 6.5 м3 *4 | |

| Hopper for finished product | 3 т | 3 т | 7 т | 7 т | 9 т | |

| Product Temperature | 120-180 ℃ | |||||

| Fuel consumption | Diesel | Diesel: 5 – 7.5 kg/t | ||||

| Coal | Coal: 13 – 15 kg/t | |||||

| Bitumen drum | 10 т | 20 т | 30 т | 30 т | 35 т | |

| Control cabin | 2.2 м | 2.2 м | 3 м | 3 м | 3.5 м | |

| Options | Bag dust filter | |||||

Advantages of mobile abrasives

The mobile asphalt plants of our company have many special advantages, they are manifested in the following aspects. Mounting and dismounting is more convenient and easier in AIMIX. The mobile asphalt plant is designed and manufactured using a modular approach, in the process only need to dismantle part of the equipment, the assembly and disassembly time is shorter. With AIMIX, moving to the next construction site can be faster due to the special tires and chassis installed. The dust filter system is advanced, will not affect the environment. Its aggregate weighing measuring device is imported from abroad, in the weighing process can automatically compensate the difference, improved the accuracy of weighing and batching. In AIMIX has advanced design and manufacturing technology, preferential and low price of asphalt plant, best after-sales service, high and high-quality products.

Compact mobile compulsory abrasive mixer type ALYJ

| Model | ALYJ10 | ALYJ15 | ALYJ20 | ALYJ30 | ALYJ40 | ALYJ60 | ALYJ80 | |

| Performance | 10 t/h | 15 t/h | 20 t/h | 30 t/h | 40 t/h | 60 t/h | 80 t/h | |

| Total capacity | With diesel fuel | 48 kW | 59 kW | 68 kW | 106 kW | 132 kW | 146 kW | 186 kW |

| With coal heating | 67 kW | 78 kW | 91 kW | 129 kW | 170 kW | 192 kW | 262 kW | |

| Inert material supply system | 3 м3 *3 | 3 м3 *3 | 3 м3 *3 | 5 м3 *3 | 5 м3 *3 | 5 м3 *3 | 5 м3 *4 | |

| Hopper for finished product | 2 т | 5 т | 5 т | 9 т | 9 т | 9 т | 20 т | |

| Product Temperature | 120-180 ℃ | |||||||

| Fuel consumption | Diesel | Diesel: 5 – 7.5 kg/t | ||||||

| Coal | Coal: 13 – 15 kg/t | |||||||

| Options | Wet filter, bag filter, control cabin, bitumen drum with heater, mineral powder drum | |||||||

Mobile asphalt plant price

Where to buy mobile asphalt batching plants better? We have a lower price for mobile asphalt concrete plant here than elsewhere. It depends on the following factors, at AIMIX the production and sales cost is low. Since our factory is located in the middle of China, where there is a lot of labor resources, the average per capita salary is low in our city, the prices of goods are also relatively cheap. These reasons help save a lot of costs to pay labor resources. We use a direct sales model from the factory without a middleman. This also significantly reduces the cost of product delivery and intermediaries will not make a profit.

Mobile abrasives are of high quality

Mobile asphalt batching plants are quality in our company. The product quality of the company deeply affects the development speed of this company. Therefore, our company has long established and passed strict quality control regime of the product. We strive to achieve such goal that there is no fake produced in our factory in the market. In addition, our company has imported advanced components from abroad, it will also ensure the stability and safety in operation.

Best after-sales service

Our company has rich export experience. If you encounter problems in using the product, you can ask our special technicians online. They will explain to you how to solve this problem. And if you require our technicians to drive up to you, it works out too. At present, our company has set up several offices abroad, more will be set up in the future to serve you better.

If you want to buy mobile asphalt concrete batching plants or find out detailed information and preferential prices, then you need to leave your email and information below. Wish you get the best mobile asphalt concrete plant.

Asphalt Concrete Plant Working Principle

Asphalt plant is more important for road construction. Its working principle is also more complicated than that of concrete plant, because it is equipped with dust filter system, dryer and combustion device, asphalt feeding device and intermediate ejector. First, belt conveyor can transfer the cold mixtures to dryer drum, and then the cold mixtures can be dried and heated, after drying and heating up, it is sent to intermediate storage bin of hot mix material, and then it is weighed and sent to forced mixing plant, where it is mixed with the hot asphalt brought from other direction. After mixing, the prepared asphalt mixtures will be brought to the hopper to store the finished product. Finally, the prepared mixtures will be discharged into the asphalt transport vehicle. The dust filter operation is done during the heating and lifting of the hot mix. These are the principles of compulsory asphalt plants.

And the working principle of continuous asphalt batching plant is different from that of drying and heating up device and concrete mixing device. The working principle of continuous asphalt plant is reflected in the fact that its drying and heating unit and concrete mixing unit are combined in one unit, which means the drying and mixing takes place in one unit and at the same time.