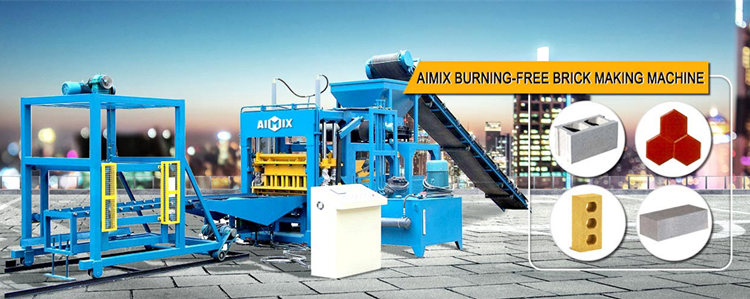

Do you want to get into the business of making paving tiles? Now you can buy brick plant equipment from our company AIMIX. Here is a large selection, a wide range of applications, our brick making equipment has different models for different scale projects. Here every block making machine price is cheaper, you can find out their prices and compare with other companies’ prices. Here the block making equipment with high quality, the manufacturing technology is modern. Do you like our brick making line?

Description and characteristics

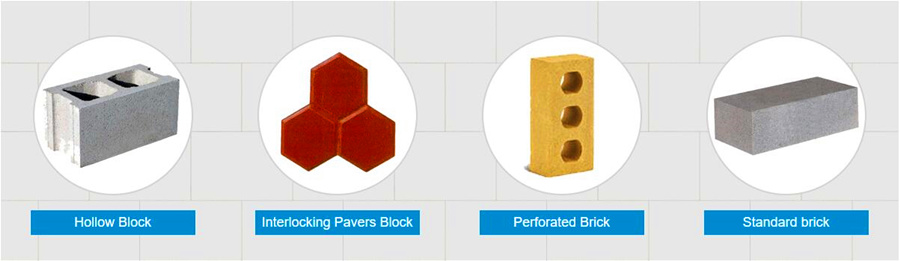

Brick production line is a complete and specialized equipment used to produce construction blocks. Our brick production line can produce a variety of building blocks. For example, it can produce paving slabs, red clay bricks, concrete slabs, various types of blocks and bricks with various sizes and applications. Until now, it can be regarded as the most advanced production equipment in the international market, it is featured by high capacity, reasonable structure, high automation, relatively small size, small space requirement, and the ability to produce a wide range of building blocks. Is this brick making machine interesting for you?

Block production line: classification

What kind of brick making equipment do you need to buy for your business? Did you know, block making equipment has different classifications and types for different facilities. For example, Block making line can be divided into two classifications: clay brick making line, and concrete block making line. Among them, the first classification refers to the traditional brick making machine. It has a long history of use, but its productivity and efficiency is relatively low. Of these, the block making machine can be divided into large, medium and small concrete block making machine in terms of productivity. A large block making machine is suitable for a larger brick making plant. Small is understood as home brick making machine, the production capacity is low, the price is cheap. Suitable for a small manufacturer to produce building blocks. Construction block making machine can be divided into automatic, semi-automatic and block making machine with their own hands according to automativeness. Do you like it?

Block making machine model ABM-12s – technical specifications

| Brick | Size(L*H*H) | Piece/Form | Formation cycle | Piece per hour |

| 200*100*60 | 38 | 18-23с | 5948-7600 | |

| 200*160*60 | 25 | 18-23с | 3913-5000 | |

| 240*115*53 | 62 | 15-17с | 12700-14400 | |

| 390*190*190 | 12 | 20-25с | 1728-2160 |

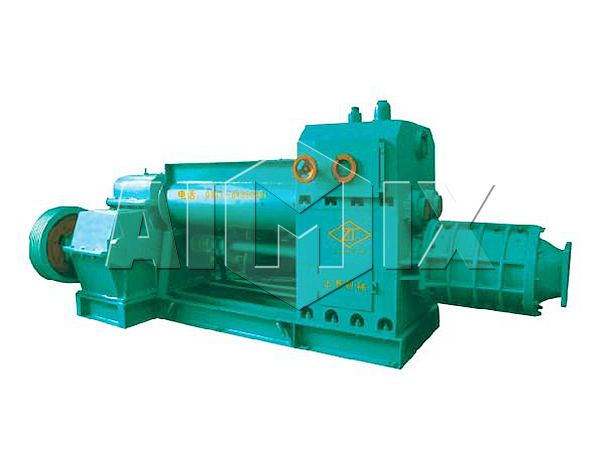

Production press for clay bricks

Which clay brick equipment do you like? With a large capacity or with a small capacity? You can find the most rational model for your business at our company AIMIX. Because our company has a complete model for export. They are all designed and manufactured according to the real market demand. At present, the clay brick machine can be divided into 9 specific models for export. Among them, the biggest machine can maximally produce 28,000 pcs/h, and its motor power is up to 447kw. It is used in large brick manufacturing factory. And among them, the smallest brick making machine can produce 4000 pcs per hour, its motor power reaches 45kW. It is suitable for small and medium brick manufacturing business. So, what kind of brick making equipment are you more interested in? You can contact us to get preferential prices and options to choose from.

Reliable equipment

Product with high quality is the main factor by which any company can continuously develop and increase its competitive power. Our company also puts great emphasis on product quality. Therefore, it has set a goal that does not allow any non-standard products to enter the market from our production plant. At the same time, it has established strict rules for the management of workers and checking product quality to avoid losses from workers’ negligence. Our company has yet adopted massive technical talents to design and develop new products. And of course, it has mastered the advanced technology for making concrete block equipments. Would you like to make a visit to our manufacturing factory to see and test our Chinese brick making machine. It also turns out, we will be glad to welcome you.

After-sales service

Do you care about the after-sales service of the products? Don’t worry! Because our AIMIX company can provide intimate after-sale service if you want to buy a block making machine. For example, we can help you install and adjust the new block making machine. Moreover, we will still carefully explain to you the way of maintenance and management. And if your equipment is something wrong, calm down! Our company will provide you with suitable spare parts in the first time to ensure the productivity and efficiency of your business. While our company has set up overseas offices and warehouses in Central Asia and Russia to offer regular repairs and inspections for your business.

With what kind of performance you wanted to buy more for your business? Now you can leave your email, number, name and real requirement below so that we can provide you with the most rational option and preferential prices. Don’t forget to check our prices and compare them with other companies to know where the brick making equipment price is preferential and rational. Wishing you success in all endeavors!