Asphalt-concrete plants (asphalt plants) are capable of producing asphalt-concrete mixes, modified and colored asphalt. These mixtures are used for the construction of highways, municipal roads, airports, ports, etc. Want to buy asphalt concrete plant at low price for road construction from China? We at Aimix Group can offer you various types of asphalt mixing plants with capacities ranging from 10tph to 320tph. We offer superior service and economical prices on abrasives to help you reduce your costs. If you are interested, please make an inquiry and leave your specific requirements below. Aimix Group offers special commercial offers and favourable prices.

Types of asphalt plants

As we all know that road construction projects have different levels, scales and construction situations. So different types of asphalt plants are necessary to meet the construction requirements. Still, at Aimix, you can find a reliable model among the wide choices. At present, our asphalt batching plants are divided into three main types according to capacity:

» mini asphalt plant;

» medium asphalt plant;

» Large asphalt plant.

According to the type of mixer, asphalt mixing plants are divided into two types:

» abz continuous production;

» abz cyclic abz.

And in terms of mobility they can be divided into two main types:

» stationary asphalt plant;

» mobile asphalt plant.

Stationary asphalt plant

It is understood as the most used asphalt production equipment, which is applied to produce asphalt concrete of different certifications. Our company offers various stationary plants for sale, which have been designed according to the scale of construction projects. They can produce asphalt at a maximum capacity of 40 ton /hour to 320 ton/hour. Stationary asphalt batching plant is equipped with compulsory mixer. Such mixer is characterized by high capacity and uniform mixing, providing the quality of asphalt concrete. In addition, the stationary abrasive mixer is equipped with a precise weighing device to ensure the rationality and accuracy of mixture proportioning.

Pros of stationary abz:

» strong performance;

» high quality finished products;

» wide range of applications.

Stationary asphalt plant ALQ series

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

| Performance | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Inert material supply system | |||||||||

| Inert material hopper volume | 4*4.5 м3 | 4*6.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 5*12 м3 | 5*12 м3 | 5*12 м3 | 6*15 м3 |

| Transport capacity | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 200 t/h | 220 t/h | 280 t/h | 360 t/h |

| Inert material heating and drying system | |||||||||

| Drying drum size | F1.2 m*5.2 m | F1.5 m*6 m | F1.5 m*6.7 m | F1.65 m*7 m | F1.8 m*8 m | F2.2 m*9 m | F2.6 m*9 m | F2.6 m*9.5 m | F2.8 m*10.2 m |

| Dryer capacity | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h | 240 t/h | 260 t/h | 360 t/h |

| Burner fuel consumption | 70-300kg/h | 100-400kg/h | 120-600 kg/h | 150-1000 kg/h | 150-1000 kg/h | 150-1400kg/h | 180-1800kg/h | 180-1800kg/h | 260-2500kg/h |

| Mixing tower | |||||||||

| Vibrating screen | 4 layers | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Inert material dosing hopper volume | 500 kg | 800 kg | 1000 kg | 1300 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4000 kg |

| Powder dosing hopper volume | 120 kg | 150 kg | 200 kg | 200 kg | 300 kg | 300 kg | 320 kg | 600 kg | 700 kg |

| Bitumen metering hopper volume | 100 kg | 120 kg | 150 kg | 150 kg | 250 kg | 250 kg | 250 kg | 480 kg | 500 kg |

| Mixing capacity | 500 kg | 800 kg | 1000 kg | 1,250 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4000 kg |

| Mixing cycles | 45 с | ||||||||

| Dust extraction system | |||||||||

| Filter pad | 230 м2 | 300 м2 | 420 м2 | 480 м2 | 550 м2 | 650 м2 | 700 м2 | 1050 м2 | 1350 м2 |

| Chimney power | 22 kW | 30 kW | 45 kW | 55 kW | 90 kW | 110 kW | 2*75 kW | 2*90 kW | 2*110 kW |

| Bitumen temperature | 140-180 ℃ | ||||||||

| Finished material hopper (options) | 20/50 tons | 20/50 tons | 20/50 tons | 60 tons | 60 tons | 120 tons | 120/200 tons | ||

| Total power consumption (depending on configuration) | 170 kW | 200 kW | 300 kW | 350 kW | 380 kW | 490 kW | 550 kW | 670 kW | 865 kW |

Would you like to know more or get their commercial offers?

A client from Russia bought a stationary abrasive mixer from our company, which needed equipment with a capacity of 80 t/h, our company Aimix offered the best option and favourable price, so that the client decided to buy the abrasive mixer there. Now our equipment was already installed at the customer’s site.

Mobile asphalt plant

It refers to an asphalt plant that enables asphalt to be moved on roads. Because it is mounted on a chassis and is moved by truck. The reliable mobility is a major advantage compared to the stationary type. In addition, the mobile asphalt plant is characterized by rapid installation and disassembly, convenient transportation. In our company mobile asphalt plant is divided into three types:

1. general mobile abz series ALYQ

It is an asphalt mixing plant which is equipped with a mobile unit. Except the mobile unit, the rest of the unit is similar to stationary type, applying forced mixer. Therefore, it is characterized by high capacity, uniform mixing and fast mobility. Their maximum capacity ranges from 60 to 160 ton/h. More details in the table below.

ALYQ Series Mobile Asphalt Plant

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 |

| Performance | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h |

| Inert material supply system | |||||

| Inert material hopper volume | 4*6.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 5*8 м3 |

| Belt power | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h |

| Inert material heating and drying system | |||||

| Drying drum size | F1.5 m*6 m | F1.5 m*6.7 m | F1.65 m*7 m | F1.8 m*8 m | F1.9 m*9 m |

| Dryer capacity | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h |

| Burner fuel consumption | 100-400/kg/h | 120-600/kg/h | 150-1000/kg/h | 150-1000/kg/h | 150-1400/kg/h |

| Mixing tower | |||||

| Vibrating screen | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers |

| Inert material dosing hopper volume | 800 kg | 1000 kg | 1300 kg | 1500 kg | 2000 kg |

| Powder dosing hopper volume | 150 kg | 200 kg | 200 kg | 300 kg | 300 kg |

| Bitumen metering hopper volume | 120 kg | 150 kg | 150 kg | 250 kg | 250 kg |

| Mixing capacity | 800 kg | 1000 kg | 1,250 kg | 1500 kg | 2000 kg |

| Mixing cycles | 45 с | ||||

| Dust filter (bag dust filter) | |||||

| Filter pad | 300 м2 | 420 м2 | 480 м2 | 550 м2 | 650 м2 |

| Chimney power | 30 kW | 45 kW | 55 kW | 90 kW | 110 kW |

| Bitumen temperature | 140-180 ℃ | ||||

| Total power (depending on configuration) | 200 kW | 300 kW | 350 kW | 380 kW | 490 kW |

2. Compact mobile abrasives ALYJ Series

This equipment is also used as compulsory equipment, having powerful capacity. But its design is relatively simple, it is not equipped with sorting device and accurate weighing device, so the asphalt mix is relatively lower quality than that of stationary abrasive concrete. Therefore, its finished products are more used for low-level road construction. The most important thing is that its cost is lower. Their maximum capacity ranges from 10 to 80 tons/hour.

ALYJ Series compact mobile concrete batching plant – features

| Model | ALYJ10 | ALYJ15 | ALYJ20 | ALYJ30 | ALYJ40 | ALYJ60 | ALYJ80 | |

| Performance | 10 t/h | 15 t/h | 20 t/h | 30 t/h | 40 t/h | 60 t/h | 80 t/h | |

| Total capacity | With diesel fuel | 48 kW | 59 kW | 68 kW | 106 kW | 132 kW | 146 kW | 186 kW |

| With coal heating | 67 kW | 78 kW | 91 kW | 129 kW | 170 kW | 192 kW | 262 kW | |

| Inert material supply system | 3 м3 *3 | 3 м3 *3 | 3 м3 *3 | 5 м3 *3 | 5 м3 *3 | 5 м3 *3 | 5 м3 *4 | |

| Hopper for finished product | 2 т | 5 т | 5 т | 9 т | 9 т | 9 т | 20 т | |

| Product Temperature | 120-180 ℃ | |||||||

| Fuel consumption | Diesel | Diesel: 5 – 7.5 kg/t | ||||||

| Coal | Coal: 13 – 15 kg/t | |||||||

| Options | Wet filter, bag filter, control cabin, bitumen drum with heater, mineral powder drum | |||||||

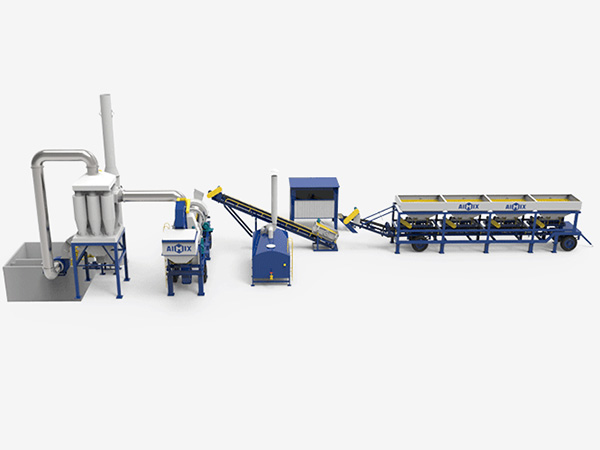

3. ALT Series Mobile Drum Abrasives

The drum abrasive dryer is a mobile cyclic machine. It is not equipped with compulsory mixer, and its drying and mixing operations are carried out in one drum. Such design allows it to reduce the production cost of asphalt plant. In addition, its simple design allows it to be put into operation in a short time (5-7 days). Its maximum capacity ranges from 20 to 100 tons per hour.

Mobile drum type concrete batching plant Series ALT

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 | |

| Performance | 20 t/h | 40 t/h | 60 t/h | 80 t/h | 100 t/h | |

| Total capacity | With diesel fuel | 34 kW | 65 kW | 105 kW | 135 kW | 170 kW |

| With coal heating | 40 kW | 75 kW | 120 kW | 165 kW | 200 kW | |

| Inert material supply system | 3.5 м3 *1 | 4 м3 *4 | 4 м3 *4 | 6.5 м3 *4 | 6.5 м3 *4 | |

| Hopper for finished product | 3 т | 3 т | 7 т | 7 т | 9 т | |

| Product Temperature | 120-180 ℃ | |||||

| Fuel consumption | Diesel | Diesel: 5 – 7.5 kg/t | ||||

| Coal | Coal: 13 – 15 kg/t | |||||

| Bitumen drum | 10 т | 20 т | 30 т | 30 т | 35 т | |

| Control cabin | 2.2 м | 2.2 м | 3 м | 3 м | 3.5 м | |

| Options | Bag dust filter | |||||

Mobile abc was assembled in the Philippines

Recently our compact mobile abrasive mixer was installed in the Philippines with the help of our engineers. Our customer decided to buy a 60 ton/h mobile abrasive plant from our company Aimix Group. Because in negotiations with the customer, our company offered special options, drawing and favourable price for the asphalt plant. Now this mobile abrasive asphalt plant has already been put into operation at the customer’s site.

Reliable supplier from China

Aimix Group company offers to buy asphalt plants of different kinds with a guarantee from China. Since its inception, the company has always strived to become a reliable supplier of construction and industrial equipment. So far, our products have been exported to many countries. Such as Russia, Kazakhstan, Uzbekistan, Kyrgyzstan, Ukraine, Belarus, Georgia, Vietnam, Bangladesh, USA and UK, etc. At present, Aimix has the following main advantages:

Wide selection, the company accepts orders for asphalt batching plant in the range of 10tph to 320tph. In addition, you can assign the components to be used, such as brand of electrical equipment, type of vibrating screen, etc.

The best asphalt plant service, Aimix has its own service teams that offers quotation, drawing, schematic and price of asphalt plant before sale, and offers installation, abz operator training, repair, providing abz spare parts and other services after sale.

An experienced supplier, Aimix has exported its machinery to many countries. In this process, it has formed special foreign trade teams and shipping department and has accumulated considerable export experience. Our company can provide a safe and effective guarantee for the export of equipment.

Guaranteed service life, Aimix provides quality asphalt batching plants and gives a reliable warranty with the equipment.

Asphalt concrete plant price is cheaper here, abz price is one of the main advantages in Aimix. Cheap labor and steel can reduce the cost of equipment. While, mass production is also suitable to reduce the production cost. Choose the right model and find out our competitive prices.

Good company reputation, you can find out the reputation of our company from our customers. We invite you to come and visit us if you are interested in our company.

Characteristics of the asphalt plant

» high automation, abz is equipped with PLC automatic control system, suitable to reduce labor cost and increase efficiency.

» Strong performance, the abrasive mixer adopts compulsory mixer, which is characterized by high productivity and uniform mixing.

» Excellent dust extraction capability. The abrasive machine is equipped with multi-stage dust extraction system: cyclone dust extraction and bag filter (or wet filter). Among them, the bag dust filter ratio can reach 99% or more.

» Wide range of application, Abz can accept different fuels such as diesel, fuel oil, natural gas, reduced gas and coal.

» high weighing accuracy. The abrasives are equipped with special weighing devices, which can automatically correct the bitumen to stone ratio error of less than 0.1%.

Asphalt concrete plant to buy with a guarantee

If you are interested in our asphalt plants, please make an application form and leave detailed requirements here, or directly send the requirements to our e-mail: Inquiry@aimixmachinery.ru After that, the company offers the best option according to your requirements and a favorable price. Check out our prices for asphalt batching plants and compare them with similar models of other companies, and decide where to buy an abrasive batching plant better for you! Good Luck to you!