You can buy asphalt batching plants cheap with a guarantee from China! Learn and choose correctly! Asphalt concrete plants are abbreviated abz, also often called asphalt mixing plants in some situation. They are component equipment for producing asphalt concrete bituminous and mineral mixtures. They can produce asphalt mix, modified asphalt mix, colored asphalt mix independently. Abz is an indispensable professional equipment in the construction of expressways, highways, urban roads, airports and ports.

Asphalt mixing plants at AIMIX

Our AIMIX has a long history of asphalt plant manufacturing, research and development since its inception. Nowadays, there is a variety of asphalt plant in AIMIX. Asphalt batching plant manufacturing and trading is one of our core competencies. At AIMIX, our asphalt mixing plant covers a wide range of applications, full function, advanced equipment, stable performance, high production efficiency, reasonable price, good after-sales service, no pollution, and energy-saving are the main advantages of our asphalt plants. With us buy abrasive asphalt plant is your right choice!

How to buy the right asphalt plant

Choosing a product is always difficult for many people because many people don’t know which is the best of all the products. It is also difficult to buy asphalt concrete plants for yourself. For there are different asphalt concrete plant in today’s market, some of them are expensive and others are of poor quality, of course the best ones exist too. Let’s now solve this issue. In fact, you only need to look at the following few key factors before you buy asphalt plant: asphalt plant price is low, quality, its performance, after-sales service, non-pollution and energy saving. Then you can already buy asphalt plant for construction project when these issues are decided.

Asphalt Concrete Plant price is cheap at AIMIX

At AIMIX asphalt plant, the price is rational and there are price concession policies for all overseas customers. For our company knows, product price is a very important limiting and influencing factor for the development speed of the company. Its production cost is relatively low at AIMIX. Our production plant is located in the central region of China. There is a large population, abundant labor force, low urban consumption, per capita wages are relatively low and product prices are low. These factors keep our plant’s labor costs relatively low and help reduce the one cost required.

Sell asphalt plant from the factory

Our company can set low prices, not only because of the low cost of labor in the production process, but also reflected in the sales process. Because our company has adopted the modern form of sales after carefully studying the traditional sales model in the market. In the traditional model, asphalt plant manufacturers have to sell their products to dealers, and then the dealers sell these products to consumers. This undoubtedly increases some unnecessary transportation costs. In addition to this, the dealers will also take some profit out of the total cost, which in turn increases the total price of the product. Increasing the price means that it is not to the benefit of the consumers. Therefore, our company directly eliminated the middle part of the sale, directly sell the asphalt plant without intermediary from the factory to consumers. This measure helps reduce the overall price of the asphalt plant.

Did you know? Our company often offers some preferential pricing to all overseas customers. For example, we give you a discount if this is the first time you buy from AIMIX. Even other preferential, such as on official holidays we also give a concession if you buy on that day.

Quality asphalt plants at AIMIX

At AIMIX, we only produce the best and highest quality asphalt mixing plants. If one company’s products are only inexpensive and the quality is not up to standard, that company cannot grow. Our company deeply agrees with this rule, so it attaches great importance to product quality. And it has long established a strict product quality inspection system. Everyone should be responsible for the parts they produce. If that part is found any problems, that person should be punished accordingly if the failure is caused by personal negligence. This regime has more or less reduced the failure rate of asphalt production equipment.

In the process of development, our company has accumulated a wealth of manufacturing experience and a large number of advanced asphalt production technologies, the most important thing is that we have also trained a group of high-tech professionals and engineers. These factors are the main reasons why our company can produce quality asphalt mixing plants. Besides those, we imported some key components from abroad to make up for our own shortcomings. These components increased the stability and safety of the asphalt plant in operation. Our company will strive to do better.

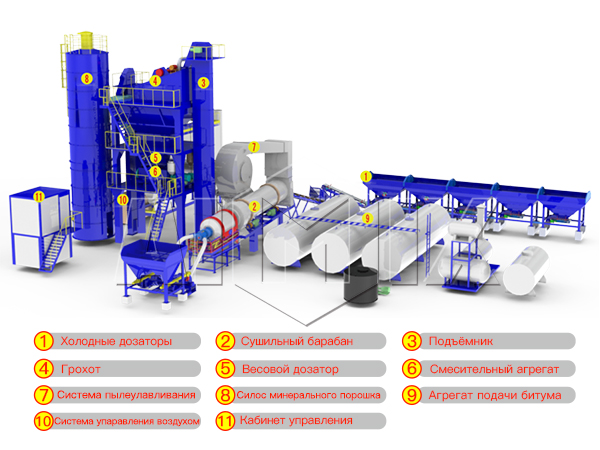

Asphalt plants: device

Asphalt plant is a relatively complex integrated system. It mainly consists of dosing device, drying device, burning device, hot material lifting device, intermediate vibrating screen, hot material storage hopper, weighing and mixing device, asphalt feeding device, filter system, finished product silo and control room. it should be noted that our asphalt plant is equipped with filter system, can reach international standard, almost has no environmental impact.

Asphalt plant: classifications

After long-term research, development and production, our company now has broad classifications of abz. Of these, each classification can be divided into some specific models in AIMIX. For example, depending on their capacity, asphalt plant in AIMIX can be divided into the following classifications: small, medium and large. And according to their mobility, they can be divided into mobile and stationary. Their capacity ranges from 10-320 tons/hour. You can find out more specifically in the bottom tables.

Stationary asphalt plant ALQ series

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

| Performance | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Inert material supply system | |||||||||

| Inert material hopper volume | 4*4.5 м3 | 4*6.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 5*12 м3 | 5*12 м3 | 5*12 м3 | 6*15 м3 |

| Transport capacity | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 200 t/h | 220 t/h | 280 t/h | 360 t/h |

| Inert material heating and drying system | |||||||||

| Drying drum size | F1.2 m*5.2 m | F1.5 m*6 m | F1.5 m*6.7 m | F1.65 m*7 m | F1.8 m*8 m | F2.2 m*9 m | F2.6 m*9 m | F2.6 m*9.5 m | F2.8 m*10.2 m |

| Dryer capacity | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h | 240 t/h | 260 t/h | 360 t/h |

| Burner fuel consumption | 70-300kg/h | 100-400kg/h | 120-600 kg/h | 150-1000 kg/h | 150-1000 kg/h | 150-1400kg/h | 180-1800kg/h | 180-1800kg/h | 260-2500kg/h |

| Mixing tower | |||||||||

| Vibrating screen | 4 layers | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Inert material dosing hopper volume | 500 kg | 800 kg | 1000 kg | 1300 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4000 kg |

| Powder dosing hopper volume | 120 kg | 150 kg | 200 kg | 200 kg | 300 kg | 300 kg | 320 kg | 600 kg | 700 kg |

| Bitumen metering hopper volume | 100 kg | 120 kg | 150 kg | 150 kg | 250 kg | 250 kg | 250 kg | 480 kg | 500 kg |

| Mixing capacity | 500 kg | 800 kg | 1000 kg | 1,250 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4000 kg |

| Mixing cycles | 45 с | ||||||||

| Dust extraction system | |||||||||

| Filter pad | 230 м2 | 300 м2 | 420 м2 | 480 м2 | 550 м2 | 650 м2 | 700 м2 | 1050 м2 | 1350 м2 |

| Chimney power | 22 kW | 30 kW | 45 kW | 55 kW | 90 kW | 110 kW | 2*75 kW | 2*90 kW | 2*110 kW |

| Bitumen temperature | 140-180 ℃ | ||||||||

| Finished material hopper (options) | 20/50 tons | 20/50 tons | 20/50 tons | 60 tons | 60 tons | 120 tons | 120/200 tons | ||

| Total power consumption (depending on configuration) | 170 kW | 200 kW | 300 kW | 350 kW | 380 kW | 490 kW | 550 kW | 670 kW | 865 kW |

ALYQ Series Mobile Asphalt Plant

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 |

| Performance | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h |

| Inert material supply system | |||||

| Inert material hopper volume | 4*6.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 4*7.5 м3 | 5*8 м3 |

| Belt power | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h |

| Inert material heating and drying system | |||||

| Drying drum size | F1.5 m*6 m | F1.5 m*6.7 m | F1.65 m*7 m | F1.8 m*8 m | F1.9 m*9 m |

| Dryer capacity | 80 t/h | 100 t/h | 120 t/h | 140 t/h | 180 t/h |

| Burner fuel consumption | 100-400/kg/h | 120-600/kg/h | 150-1000/kg/h | 150-1000/kg/h | 150-1400/kg/h |

| Mixing tower | |||||

| Vibrating screen | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers |

| Inert material dosing hopper volume | 800 kg | 1000 kg | 1300 kg | 1500 kg | 2000 kg |

| Powder dosing hopper volume | 150 kg | 200 kg | 200 kg | 300 kg | 300 kg |

| Bitumen metering hopper volume | 120 kg | 150 kg | 150 kg | 250 kg | 250 kg |

| Mixing capacity | 800 kg | 1000 kg | 1,250 kg | 1500 kg | 2000 kg |

| Mixing cycles | 45 с | ||||

| Dust filter (bag dust filter) | |||||

| Filter pad | 300 м2 | 420 м2 | 480 м2 | 550 м2 | 650 м2 |

| Chimney power | 30 kW | 45 kW | 55 kW | 90 kW | 110 kW |

| Bitumen temperature | 140-180 ℃ | ||||

| Total power (depending on configuration) | 200 kW | 300 kW | 350 kW | 380 kW | 490 kW |

Mobile drum type concrete batching plant Series ALT

| Model | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 | |

| Performance | 20 t/h | 40 t/h | 60 t/h | 80 t/h | 100 t/h | |

| Total capacity | With diesel fuel | 34 kW | 65 kW | 105 kW | 135 kW | 170 kW |

| With coal heating | 40 kW | 75 kW | 120 kW | 165 kW | 200 kW | |

| Inert material supply system | 3.5 м3 *1 | 4 м3 *4 | 4 м3 *4 | 6.5 м3 *4 | 6.5 м3 *4 | |

| Hopper for finished product | 3 т | 3 т | 7 т | 7 т | 9 т | |

| Product Temperature | 120-180 ℃ | |||||

| Fuel consumption | Diesel | Diesel: 5 – 7.5 kg/t | ||||

| Coal | Coal: 13 – 15 kg/t | |||||

| Bitumen drum | 10 т | 20 т | 30 т | 30 т | 35 т | |

| Control cabin | 2.2 м | 2.2 м | 3 м | 3 м | 3.5 м | |

| Options | Bag dust filter | |||||

Compact mobile concrete mixing plant Series ALYJ

| Model | ALYJ10 | ALYJ15 | ALYJ20 | ALYJ30 | ALYJ40 | ALYJ60 | ALYJ80 | |

| Performance | 10 t/h | 15 t/h | 20 t/h | 30 t/h | 40 t/h | 60 t/h | 80 t/h | |

| Total capacity | With diesel fuel | 48 kW | 59 kW | 68 kW | 106 kW | 132 kW | 146 kW | 186 kW |

| With coal heating | 67 kW | 78 kW | 91 kW | 129 kW | 170 kW | 192 kW | 262 kW | |

| Inert material supply system | 3 м3 *3 | 3 м3 *3 | 3 м3 *3 | 5 м3 *3 | 5 м3 *3 | 5 м3 *3 | 5 м3 *4 | |

| Hopper for finished product | 2 т | 5 т | 5 т | 9 т | 9 т | 9 т | 20 т | |

| Product Temperature | 120-180 ℃ | |||||||

| Fuel consumption | Diesel | Diesel: 5 – 7.5 kg/t | ||||||

| Coal | Coal: 13 – 15 kg/t | |||||||

| Options | Wet filter, bag filter, control cabin, bitumen drum with heater, mineral powder drum | |||||||

Best after-sales service

So far, our products have already been exported to more than 30 countries such as Russia, USA, Pakistan, etc. in this process, our company has possessed a perfect export system and after-sales service system. If your asphalt plant has something wrong or you don’t understand something about the usage that you bought from AIMIX, you can contact us, and we will solve your problem sooner. And if you need, we can also send our technicians to come to you to solve your problem. Now our company has set up some offices overseas, in the future will still create more to serve you faster and better.

Do you want to buy asphalt mixing plants or find out detailed information and discounted prices? Then you only need to leave your info and email below, the rest we will do! I wish you all the best and get a good asphalt mixing plant!